Measuring System for Semifinished Products, such as T-Beams and U-Irons

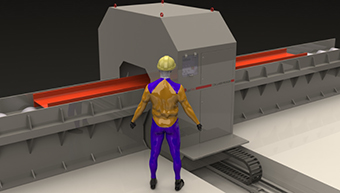

The profile measurement system is state-of-the art compact device, using up-to-date high-speed cameras, light section sensors and powerful laser line sensors. It is installed in an O-frame for being protected against high ambient temperatures.

The system is designed for detecting following materials:

The system is designed for detecting following materials:

- Supporter IPE 120 - IPE600

- HE80 – HE400

- U-irons U80 – U450

Following process requirements are considered:

- Permitted rolling speed up to max. 10 m/s

- Rolled bar length up to 100 m

- Staff aftermath 42 s minimum

- Material temperature > 850 °C to < 1,150 °C

- Width of roller table 1000 mm

System design:

- Solid steel frame construction with tunnel measurement, embedded measuring windows, thermal insulation, cooling of the measuring tunnel, entrance to the measuring electronics on both sides, integrated air conditioning of the built-in sensors, distributed peripheral monitoring system

- Framework for integrating measuring sensors (light section sensors, high-speed cameras and line lasers)

- Laser-Doppler sensor

- Control unit

- User workstations

- Calibration tool

- Adjustable measuring frame (all lines via drag chain)

Software:

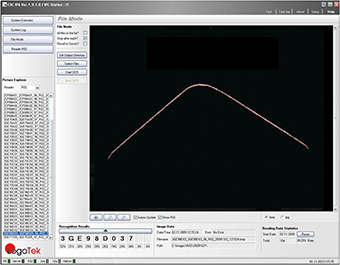

- User-software consisting of interfaces for control, measurement and HMI

- Customer-specific visualization

- Interface to operating computer

- Adaptation to material formats

- Adapting HMI

- Access to 2-D data-records, 3-D visualization of measurement results

- Printouts of protocols

- Calibration via software plus reference tools

Function:

- Profile height

- Width and thickness of flanges

- Web thickness

- Web centering (STAM)

- Surfaces

- Weights

- Rolled bar length

- Surface analysis (holes, shells, waves)

Calibration:

- Via software and reference standard

Media supply:

- Supply voltage 400 V

- 2 kVA connected load

- Cooling water 100 l/min (optional closed cooling circuit with heat exchanger)

- Air pressure 4 bar / 200 l/min

Considering influencing environmental factors such as,

- High ambient temperatures

- Material temperatures up to 1,150 °C

- Dirt, dust

- Vibrations, shocks