Application examples

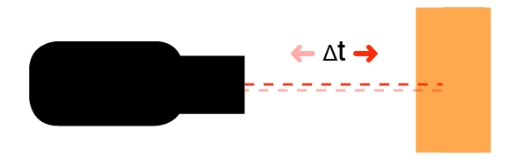

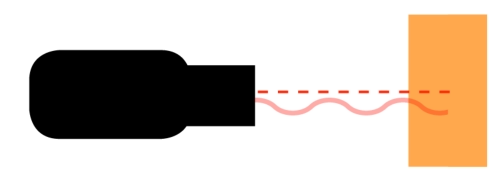

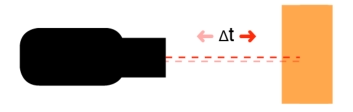

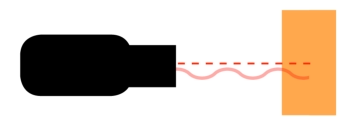

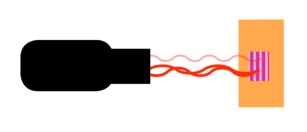

1. Emission of laser pulses in millisecond intervals

2. Determination of the time difference between output and input pulse

3. Calculating the distance from the time difference

Application examples

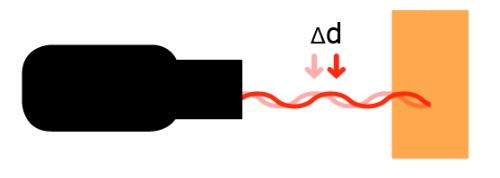

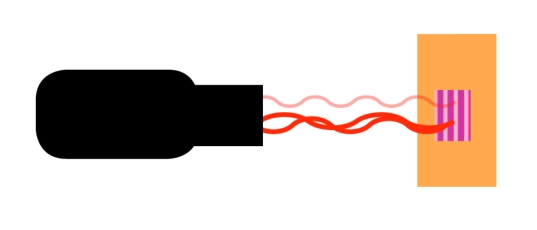

2. The Phase-shift method

MeASURING PROCEDURE

1. Emission of modulated laser light

2. Comparison of the reflection signal with the reference measurement

3. Distance calculation based on the phase shift between output and input wave

•

Material presence, width and parallelism

determination

•

Permanent position detection and positioning

•

Material flow tracking; event reporting

•

Frame cutting and cutting of semi-finished products

•

Edge detection in the casting process

•

Coil position and residual length measurement

•

Level measurement of gas containers

•

Loop control in the silo

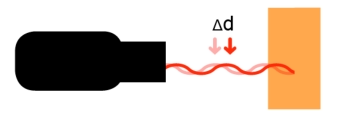

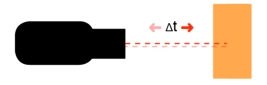

3. The Pulse backmixing method

SPECIAL FEATURES

1. Very high time resolution of 10 -12 (ToF laser 10 - 9)

2. Calibration pulse with time stamp before each measurement

3. Very high measurement rate with modulated light as pulse (no continuous light)

Application examples

•

All high-temperature processes that require high measuring rates

This method is a combination of phase-shift and time-of-

flight measuring.

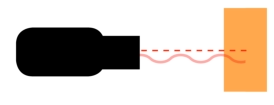

4. The Laser-Doppler-Interferometry

MeASURING PROCEDURE

1. Generation of a laser Doppler stripe by two laser beams on the

product surface

2. Collection of the reflected Doppler signal by the receiving optics

3. Signal processing into accurate, reliable and repeatable data

Application examples

•

All continuous production processes

•

Plastic sheet production

•

Paper and film production

•

Steel production

•

Tube and cable production

•

Textile production

1. The electro-optical Time-of-Flight method

MeASURING PROCEDURE

•

Position monitoring over long ranges

•

Level measurements, tilt heights

•

Ship docking

•

Positioning of loading systems

In order to cover the widest possible range of applications, our loke measuring systems utilise various highly developed measuring methods.

WEBSITE HOLDER

KEMPF GmbH & Co. KG

Otto-Hahn-Straße 5

69190 Walldorf

GERMANY

In order to cover the widest possible range of applications, our loke measuring systems utilise various highly

developed measuring methods.

1. Emission of laser pulses in millisecond intervals

2. Determination of the time difference between output and input pulse

3. Calculating the distance from the time difference

Application examples

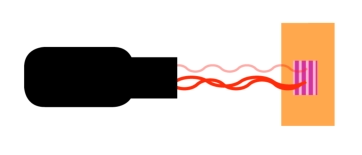

2. The Phase-shift method

MeASURING PROCEDURE

1. Emission of modulated laser light

2. Comparison of the reflection signal with the reference measurement

3. Distance calculation based on the phase shift between output and input wave

Application examples

•

Material presence, width and parallelism

determination

•

Permanent position detection and positioning

•

Material flow tracking; event reporting

•

Frame cutting and cutting of semi-finished

products

•

Edge detection in the casting process

•

Coil position and residual length measurement

•

Level measurement of gas containers

•

Loop control in the silo

SPECIAL FEATURES

1. Very high time resolution of 10 -12 (ToF laser 10 - 9)

2. Calibration pulse with time stamp before each measurement

3. Very high measurement rate with modulated light as pulse (no

continuous light)

Application examples

•

All high-temperature processes that require high measuring rates

3. The Pulse backmixing method

This method is a combination of phase-shift and time-of-flight

measuring.

4. The Laser-Doppler-Interferometry

MeASURING PROCEDURE

1. Generation of a laser Doppler stripe by two laser beams on the product surface

2. Collection of the reflected Doppler signal by the receiving optics

3. Signal processing into accurate, reliable and repeatable data

Application examples

•

All continuous production processes

•

Plastic sheet production

•

Paper and film production

•

Steel production

•

Tube and cable production

•

Textile production

1. The electro-optical Time-of-Flight method

MeASURING PROCEDURE

•

Position monitoring over long ranges

•

Level measurements, tilt heights

•

Ship docking

•

Positioning of loading systems

COPYRIGHT © 2025 KEMPF GMBH & CO. KG - ALLE RECHTE VORBEHALTEN

WEBSITE HOLDER

KEMPF GmbH & Co. KG

Otto-Hahn-Straße 5

69190 Walldorf

GERMANY

WEBSITE OWNER

KEMPF GmbH & Co. KG

Otto-Hahn-Straße 5

69190 Walldorf

GERMANY

COPYRIGHT © 2025 KEMPF GMBH & CO. KG

ALL RIGHTS RESERVED

•

Position monitoring over long ranges

•

Level measurements, tilt heights

•

Ship docking

•

Positioning of loading systems

1. Emission of laser pulses in millisecond

intervals

2. Determination of the time difference

between output and input pulse

3. Calculating the distance from the time

difference

Application examples

2. The Phase-shift method

MeASURING PROCEDURE

1. Emission of modulated laser light

2. Comparison of the reflection signal with the

reference measurement

3. Distance calculation based on the phase

shift between output and input wave

Application examples

•

Material presence, width and parallelism

determination

•

Permanent position detection and

positioning

•

Material flow tracking; event reporting

•

Frame cutting and cutting of semi-

finished products

•

Edge detection in the casting process

•

Coil position and residual length

measurement

•

Level measurement of gas containers

•

Loop control in the silo

3. The Pulse backmixing method

SPECIAL FEATURES

1. Very high time resolution of 10 -12 (ToF laser

10 - 9)

2. Calibration pulse with time stamp before

each measurement

3. Very high measurement rate with modulated

light as pulse (no continuous light)

Application examples

•

All high-temperature processes that

require high measuring rates

This method is a combination of phase-shift

and time-of-flight measuring.

4. The Laser-Doppler-Interferometry

MeASURING PROCEDURE

1. Generation of a laser Doppler stripe by two

laser beams on the product surface

2. Collection of the reflected Doppler signal by

the receiving optics

3. Signal processing into accurate, reliable and

repeatable data

Application examples

•

All continuous production processes

•

Plastic sheet production

•

Paper and film production

•

Steel production

•

Tube and cable production

•

Textile production

1. The electro-optical Time-of-Flight method

MeASURING PROCEDURE

In order to cover the widest possible range of

applications, our loke measuring systems utilise

various highly developed measuring methods.

Distance &

Level

Speed &

Length

Hot surfaces

Measuring methods