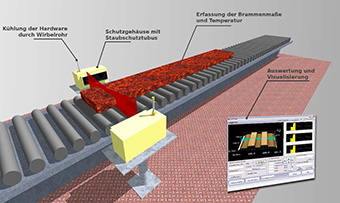

LoPROF - Measuring System for Side Profiles of Slabs and Billets

The LoProf measuring system has been developed for detecting side profiles of slabs and billets during the casting process. Based on the measured data it is possible to take direct effect on the process speed to avoid material deformation.

LoPROF system design:

- 2x 2-D laser scanner in an air-purged, temperature controlled enclosure protection housing, ambient temperature up to 120 °C

- For material surface temperatures up to 1,500 °C

- Pyrometer for continuous temperature measurement of the material

Software:

- Easy to use software

- Customer specific visualization

- Interface to operating computer

- Adaptation to material formats

- Archiving of data and access to data archive 2-D, 3-D visualization of the measured results

- Printouts of protocols

- Program tool for testing and calibration

Function of LoPROF:

- Continuous monitoring of side profile and edge thickness

- Width measurement

- Optional: length detection for downstream processes

Calibration:

- By using a calibration standard integrated in the software

Considering environmental factors such as,

- Ambient temperatures

- Material temperatures up to 1,500 ° C

- Dirt, dust

- Vibrations, shocks