ProfilIST - Highly Accurate System for Measuring Length

The measuring system is used for determining length of tubes, rods and profiles within millimeter precision during running processes. The wall thickness should be ≥ 8 mm, the maximum object length can be up to 40 meters. The accuracy of tolerance is constantly < 2 mm over the whole measuring range. The measured value output is visualized on a large display, while simultaneous data transmission of measured values via EtherNet (TCP/IP).

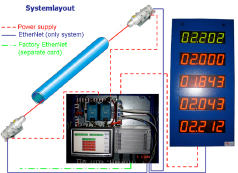

System design of ProfilIST:

- 2 laser sensors with Ethernet TCP/IP

- Housing in industrial PC, operating via touch screen, Multi Switch, buffered voltage supply 24 VDC

- Large display

Software:

- Easy to use software

- User-friendly interface handled via touch screen

- Reduction of inputs on one calibration, routine processes are running in background

- Archiving the last 5 measured values

- Optional: transfer of data via Ethernet TCP/IP to a higher-leveled computer

Function of ProfilIST:

- Detecting distances

- Transmission of the measured distance values to PC, calculating the actual length in real time

- Transfer of measured data to large display, forwarding data to the control station

- Shows the last 5 measured values on the display

Calibration:

- One-shot calibration for reference of both sensors by using a test item

Considering the influence of environmental factors such as,

- High ambient temperatures

- Material temperatures up to 1,450 °C

- Dirt, dust

- Vibrations, shocks

- Different material surfaces