The Tube Inspector System LMC-S-TIN 500

The measuring system provides data for an exact cut position on the pipe end. Simultaneously it is detecting the tube contour and length of the tube for following processes.

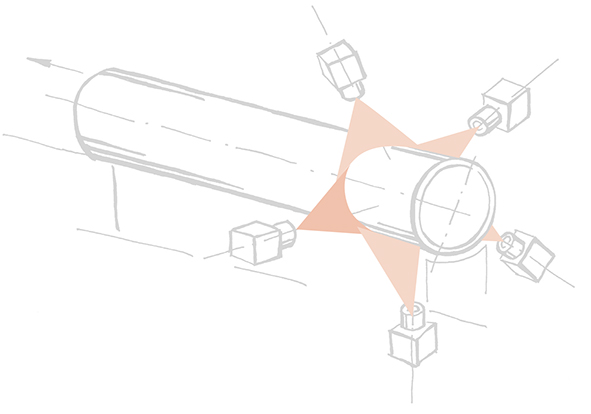

System design of LMC-S-TIN 500:

- Star-shaped arrangement of Camera system while complete contour detection

- Integration of the camera and sensors in a robust, fully heat-insulated protection body, material temperatures up to 950 °C

- Speed up to 4 m/s

Software:

- User friendly IPA-Software

- Data are graphically recorded and archived

- Visualization software enables access to data archive

Function of LMC-S-TIN 500:

- Precise cutting position on the pipe end

- Detecting pipe contour (geometry of the pipe)

- Length of the tube

- Service, remote diagnostics and maintenance via Ethernet TCP/IP

Calibrating:

- One-time calibration of the system by using reference measurement (commissioning) via test

item

item

Considering the influence of environmental factors such as,

- High ambient temperatures

- Material temperatures up to 1,450 ° C

- Dirt, dust

- Vibrations, shocks

- Different material surfaces