SPM - Slab Profiler for Controlling Geometric Profiles of Slabs and Billets

The measuring system SPM-Slab Profiler Measurement System is designed as a measuring device used during the casting process of slabs and billets. It provides the user with current process data, regarding the entire geometric structure of every product.

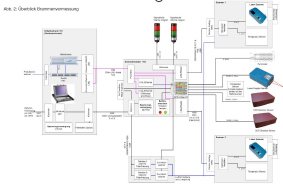

System design of the SPM-Slab Profiler:

- Frame with integrated measuring tunnel and protective housings, water cooled and air cooled, equipped with 2x laser scanners for profile detection and width measurement

- Pyrometer for continuous temperature measurement on the product

- Laser Doppler for length detection

- Laser distance sensors for thickness measurement on the product

- All In One PC, including 22" display for visualization

- Calibration standard

Software:

- User friendly software

- Determine length, width and thickness as well as temperature profile on the product

- Optional skis averaging

- Visualization of collected data, saved in different data typs, 3-D plot

- Storage and backup of the collected data on a server

- Display of the filed data

Functions of the SPM-Slab Profiler:

- Determining length, width, thickness and profile / contour and temperature of slabs and billets

- Optional:

- Multi-lane thickness measurement

- Optional ski and camber detection

Calibrating the SPM-Slab Profiler:

- Calibration via software and reference standard

Considering influencing environmental factors such as,

- High ambient temperatures

- Material temperatures up to 1400 ° C

- Dirt, dust

- Vibrations, shock